Focus on developing the circular economy and minimizing climate impact

Durat is now focusing on the development of solid surface materials. Key development projects include increasing the share of recycled materials in production and the use of our own and other industrial side-stream materials, which will lead to the development of a completely new type of Durat materials.

The aim is to implement the circular economy even more effectively in all areas of operations and to significantly reduce the climate impact. Durat aims to be carbon neutral by 2025 at the latest, when Finland will switch to life-cycle carbon footprint regulation for new construction. To achieve this target, the company's carbon footprint and environmental impact indicators will be calculated in accordance with EN 15804.

The targets will be achieved by investing in strong in-house material development and modernisation of production equipments. A key focus is on the research facilities that have just been renewed and designed to meet current needs. New product development facilities are being completed at the factory, which will allow more advanced development work to be carried out in-house.

The new investments will enable the company to further strengthen the implementation of circular economy principles. The ultimate goal of the development projects is a fully closed material loop.

Getting emissions under control

A key objective of development projects has always been to monitor emissions from production even more carefully. Accurate monitoring also helps to build the most effective methods for reducing emissions.

The environmental impact of new Durat products is carefully assessed in the development of materials. These are essential criteria for the selection of raw materials, among other things.

Minimizing environmental impact is the basis of all Durat's activities. Since the company was founded more than thirty years ago, a key starting point has been the recycling of plastic waste. Today, impact reduction objectives are also important because of the growing demand for sustainable interior and building materials.

In order to provide reliable information on the environmental impact of our activities, we have drawn up an EPD, Environmental Product Declaration for the traditional Durat material and calculated its carbon footprint. As our material development produces new materials, we also produce an EPD and a carbon footprint calculation for them.

An EPD is a third-party verified document that describes the environmental impact of a material. The information and calculations presented in the EPD are based on a life cycle analysis (LCA) of the Durat solid surface throughout its life cycle, from raw material supply to final disposal.

"As throughout our company's history, we continue to strive to be at the forefront of innovation. We do things that we believe contribute to the well-being of our environment. Our actions are not only guided by existing regulations, but in line with our own values, we try to do as much as possible to ensure that our operations are ethically sustainable. For example, we have been operating according to the principles of the circular economy since before the term circular economy existed," says Heikki Karppinen, CEO.

Mervi Puska brings courage and a scientific approach to development projects

Mervi Puska, Doctor of Philosophy and Materials Chemist, Durat's Director of Materials Development, took up her position in 2021. Mervi's expertise and experience brought a whole new dimension to the company's product development work.

Material development director Mervi Puska brings courage to Durat's material development.

"My most extensive work experience is in research and product development of functionally active composite materials, as well as in manufacturing, testing and research of biodegradable plastics and various medical biomaterials. During my career of about 28 years, I have held research, product development and teaching positions, as well as expert positions, mostly in academic research units. In the private sector, I have worked in research, development and innovation for more than seven years." Mervi is also an docent in medical biopolymer research at the University of Turku since 2011.

"It has been great to be able to apply the knowledge gained in research to practical product development projects. Chemical reactions and material science phenomena are always the same, whether in the lab or in real life.

For me, transferring research knowledge into practical applications is relatively easy. Although I switched from research on medical composite materials to building materials, I feel like I've just picked up where many unfinished projects left off at university," says Mervi.

"I've always done a lot of work in the lab. It's a way of working that suits me and I like it. Laboratory work keeps me in touch with practical work and often gives me good insights."

Mervi says that she likes to do "out of the box" tests: "I try to think broadly and not in a formulaic way.

At university, colleagues sometimes wondered about my unusual composite samples. But they were always related to a bigger picture or project."

"I constantly try to look for solutions in a creative and versatile way. Colleagues watching what I was doing from the sidelines may not have immediately realised how my experiments related to the bigger picture and the larger theme. I had a mentor for many years, Professor Emeritus of Surgery at the University of Turku, Allan J. Aho, who was a very creative and encouraging partner. He had great ideas. He also inspired me to try bold experiments and taught me to think from a slightly different perspective than I was used to."

"In science, you need to go deep into your own field of research and subject area, but in practice you need a broader range of skills in many other areas. My boundary-breaking experiments in materials science and composite structures at university have now proved very useful in Durat's product development work," Mervi smiles happily.

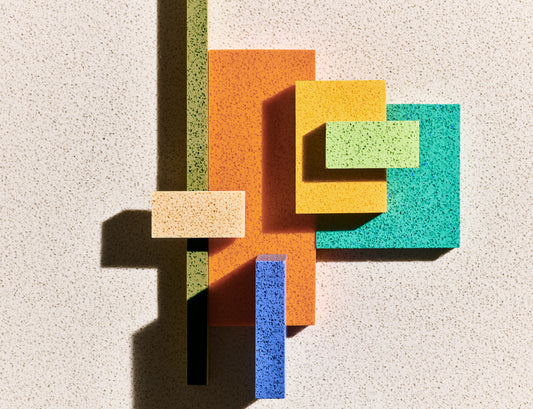

Inspired by Durat colours

Working at Durat has made colour an important part of Mervi’s life. She works surrounded by cans of colour.

"Durat colours brought a whole new dimension to my work. In my previous jobs, I worked with a fairly limited colour palette, such as bone cement and dental materials. Even a researcher interested in aesthetics is inspired by Durat's jars of colour paste. It's great to see how all these amazing colours are made and to be involved in their development," says Mervi.